Ningxia shizuishan mining region 19 dead, all coal mines to stop production self-examination

28th at 40 hours, held in shizuishan city in Ningxia Lin Li coal co Colliery gas explosion press conference.

The morning of September 27, 2016 at seven o'clock sharp, located in shizuishan in Ningxia coal limited third Lin Li Hao Jing, a gas explosion occurred. So far, 19 people have been killed, there are still 1 missing, is in search and rescue.

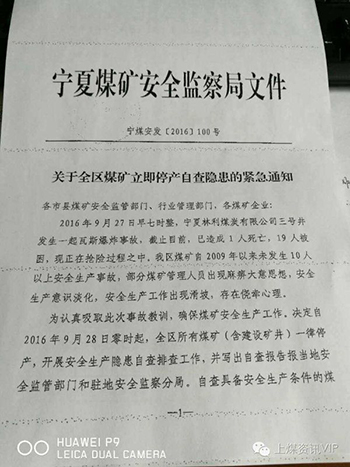

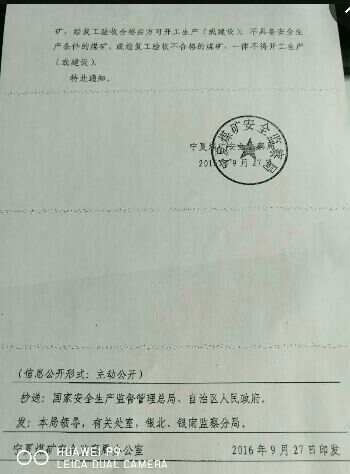

On September 27, the Ningxia coal mine safety supervision Bureau as to absorb the lessons of this incident to ensure coal mine safety production work, issued an emergency notice. Notice that since September 28, 2016 0 o'clock, all the coal mines in the autonomous region (including the building of mine) will be shut down, safety hidden trouble self-check work carried out, and to write a self-examination report filed with the local safety supervision and management departments and resident safety supervision Bureau. Self-examination to the safety conditions of coal mines, return acceptance before they can start production (or build), does not have the conditions for safe production of coal mines, or return the unqualified acceptance of coal mining, are not allowed to start production (or building).

According to the Shanghai trading center information:

A Ningxia coal prices: there are four coal mines with annual output of 12 million tons of coal, with an annual output of 1.2 million tons of coking plants, mainly the production of coking coal. Environmental checks plus in the near future coking coal supplies two factors result in coking plant starts at around 60%, reduce the yield of about 1 million tons per month, the overall tight Coke supply local. Now the Shenhua Ningxia coal industry marketing company Ning Shuojiao 25# God coking factory included 730 Yuan/ton, the shenning jinneng 1/3 coking factory tax 550 Yuan per ton.

Less Ningxia local steel mills, coke above 80% are headed south, Tangshan, Hebei and other places. Tangshan steel rising purchase prices of coke and cast, and coke production has much to do in the area, embodied in the control volume shipment in Ningxia, Mongolia and Ning area compared to the coke rate and Tangshan, Hebei, Shanxi, 60 Yuan/ton higher tariffs. Although the quality of comparative disadvantage with the Shanxi, Ningxia Coke for medium and small steel mills, need not be level or a level parameter matching, Ningxia can produce secondary Coke can meet the needs of downstream users.

Ningxia coking capacity how many? 6 coking enterprises in Ningxia, adding up to capacity in less than 10 million tonnes, but around 27 coking enterprises in Ningxia up capacity at about 43.8 million tons, accounting for 10% was not made in China in coking coal wash rate is very high.

Ningxia's coke output and how much? Coke cent in Ningxia exported. Here's a special case, ferro-alloys are more concentrated, was to use semi-Coke, but because the Shenmu coal mines this year limiting the production of Ferroalloy enterprises are therefore collectively using coke instead of blue carbon, so the local Coke pin capacity has increased significantly. Here is similar can replace semi-Coke Coke Coke, Ferroalloy production of semi-Coke advantage over Coke, the price is cheaper. 5 million tons of iron alloy in the local demand for Coke, our enterprise there are 1.8 million tons of Coke to supply the local needs of ferroalloys, so our business is 1.8 million tons of Coke to sell 3 million tons were exported.

Sources of raw coal problem? Original production level coke of when has from Shanxi procurement had coking coal, near 10 years to especially 2012 yiqian, Ningxia and Shanxi regional is Exchange of, but 2012 yihou not Exchange has, main reasons also is, while, Shanxi coking enterprise in 2012 upgrade yihou General of export resources reduced has, on the is because with the regional market concentrated of, we and Shanxi market has overlap, freight aspects price poor shortened, so coking coal no exchange of conditions has, Shanxi coal about basic and locally produced a price, Shanxi and Shanxi local coal pulled down a price, no price difference between Ningxia and Shanxi coking coal circulation cannot be formed.

When landlords Coke can meet the needs of bonding? Our landlord Jiao Zhanbi around 10%, meager lean coal in 15%, residual fat coal and sulphur in coke and one-third, coking coal resource in a niche in the local varieties, coking coal mined is less than 30%. Local coal source can meet we coking factory 70% of raw materials needs, local has 5 home coking factory no himself of coal mine, other coking factory are has himself of coal mine, local coking factory and Shanxi different of place is local is since with coal mine of coking factory many, policy provides, if himself has coal mine must himself has supporting of downstream coal chemical, no coal chemical of coal mine or reverted State-owned, or find local big enterprise merger, coal boss not willing to merger, so are established himself of coking factory, And 20.3 million tons of small coking plants built for about 1 million tons of coking plants also 2.003 billion tons of Coke. If the Chinese market downside, prices on prices of coking plant in Ningxia in the process a great deal, because demand around the end and the Ningxia Hui autonomous region is far form the location vulnerable, when market prices lagging in Ningxia because the cycle is slow to reach. We now is call Monning and Shanxi, and Hebei often Exchange, do information shared, Ningxia because this year limiting efforts on compared big so we mention rose of time compared early, this year March early has first wave up rose, but market accept degree than poor, real into rose in March end of, Ningxia area location advantage not obviously so on market close on not special tight, especially in price aspects, but price of words on special fast. Environmental monitoring for this situation, needs funding of 1 million tons of coking plant 1-1.500 million, green needs to come out of the 40 million plus an environmental device, coking plants usually do not want to do, only limiting emissions, cut production to meet environmental protection requirements. Cast, and Ning area coking factory are is to tie coal mine of operation only construction of coking factory, equivalent to coking factory was on not main industry, General boss must input 3 points one of around of funds volume in coking aspects, so they wishes insufficient, mining can sales to China around, coal of profit can make up Coke profit of missing, so can through more open mining, sales coal increased profit, didn't necessary increased coke of production.

Shanxi and Ningxia region and coking plant in the building can meet the environmental standards, but has a special factor in the production process in coking plant, coke oven fan trips and blackouts in the process runs the yellow smoke, take tobacco in environmental monitoring process as their emissions, is the result of normal emergencies, environmental monitoring and environmental protection issues.

Last year, the most difficult times, 15% is the zero-yield banking, 25% coke oven is limiting production to about half, there are about 30% productions 70%, the remaining 20% are at full capacity, production didn't drop.

Wuhai coking coal coking enterprises considered it? Mongolian coal is generally not strongly bonded, plastic layer is not high, and is likely to cause instability of thermal strength of Coke, so even a small amount of Mongolia coal can replace the primary focus, but the large amount of data displayed, Mongolia coal coking coal is not replaced. Mongolian coal blending ratio on 5% Coke quality and stability, once you achieve a percent, you vary the basic quality of Coke. Mongolian coal usage limit in the Ningxia Hui autonomous region is 10%, but Shanxi is different and strongly caking coal in Shanxi province, can match with the Mongolian coal, Shanxi can be used to 25%.

(Editors: Biao Guo UN832)

2016-09-28 13:51:38

Surging news

宁夏石嘴山矿难已致19死 全区所有煤矿停产自查

28日零时40分许,宁夏石嘴山市召开宁夏林利煤炭有限公司煤矿瓦斯爆炸事故新闻发布会。

2016年9月27日早七时整,位于宁夏石嘴山市的宁夏林利煤炭有限公司三号井发生一起瓦斯

爆炸事故。截至目前,已造成19人遇难,仍有1人下落不明,正在搜救中。

9月27日,宁夏煤矿安全监察局为认真吸取此次事故的教训,确保煤矿安全生产工作,印发紧急通知。通知指出自2016年9月28日零时起,全区所有煤矿(含建设矿井)一律停产,开展安全生产隐患自查排查工作,并写出自查报告报当地安全监管部门和驻地安全监察分局。自查具备安全生产条件的煤矿,经复工验收合格后方可开工生产(或建设),不具备安生生产条件的煤矿,或经复工验收不合格的煤矿,一律不得开工生产(或建设)。

根据上海煤炭交易中心的资料:

宁夏某煤企:有四座煤矿和年产量1200万吨的洗煤厂,年产量120万吨的焦化厂,主要生产焦煤。近期环保检查加上焦煤供应紧张两个因素,导致焦化厂开工率在60%左右,每个月减少产量100万吨左右,整体焦炭供应量局部偏紧。目前神华宁夏煤业运销公司神宁朔焦牌25#焦精煤出厂含税730元/吨,神宁金能1/3焦精煤出厂含税550元/吨。

宁夏当地钢厂较少,因此焦炭80%以上都要销往南方、河北唐山等地。唐山钢厂焦炭采购价格不断上涨和蒙、宁一带焦炭限产有很大关系,具体体现在宁夏发运方面控制运输量,蒙、宁一带焦炭到河北唐山运价和山西相比,运价要高60元/吨。虽然质量与山西相比较劣势,但是宁夏焦炭适用于中小型钢厂,不一定要一级或者准一级可以参配,宁夏可以直接生产二级焦就可以满足下游用户需求。

宁夏焦化方面总产能有多少?宁夏有6家焦化企业,加起来产能在不到1000万吨,但是宁夏周边有27家焦化企业加起来产能在4380万吨左右,占中中国国产能不到10%,焦煤自洗率很高。

宁夏焦炭外销量有多少?宁夏焦炭70-80%外销。这边有一个特殊的情况,铁合金比较集中,原来是要使用兰炭的,但是因为今年神木煤矿集体限产所以导致铁合金企业大量使用焦炭代替兰炭,所以当地焦炭地销能力大幅提升。这边生产的焦炭就是类似完全可以替代兰炭的焦炭,铁合金生产方面兰炭比焦炭要有优势,价格比较便宜。当地有500万吨的铁合金的焦炭需求,我们企业有180万吨的焦炭可以供应到当地的铁合金需求上,所以我们企业焦炭180万吨是地销,300万吨是外销。

原料煤来源问题?原来生产一级焦的时候有从山西采购过焦煤,近10年来尤其是2012年以前,宁夏和山西区域是互通的,但是2012年以后不互通了,主要原因还是,一方面,山西焦化企业在2012年提升以后总体的外销资源减少了,另一方面就是因为随着各区域市场集中化,我们和山西市场有重叠,运费方面价差缩短,所以焦煤没有互通的条件了,山西煤拉过去基本和当地产的一个价,当地的煤拉倒山西也和山西一个价,宁夏和山西焦煤之间没有价差,流通无法形成。

当地主焦能满足粘结的需求嘛?我们当地主焦占比在10%左右,贫瘦煤在15%左右,剩余是肥煤、中硫肥和三分之一焦,焦煤资源在当地算是小众的品种,焦煤可采量不到30%。当地煤源可以满足我们焦化厂70%的原料需求,当地有5家焦化厂没有自己的煤矿,其他焦化厂都有自己的煤矿,当地焦化厂和山西不同的地方就是当地是自带煤矿的焦化厂很多,政策规定,如果自己有煤矿必须自己有配套的下游煤化工,没有煤化工的煤矿要么收归国有,要么找当地大企业兼并,煤老板不愿意兼并,所以都建立自己的焦化厂,而且20-30万吨的小型焦化厂都建成为100万吨左右的焦化厂,也有200-300万吨的焦炉存在。如果中国市场下行,压价过程中对宁夏焦化厂压价比较厉害,因为需求端周边有供应,宁夏比较远,形成区位上的弱势,市场涨价的时候宁夏比较滞后,因为到达的周期比较慢。我们现在也是号召蒙宁和山西、河北经常交流,做到信息共享,宁夏因为今年限产力度就比较大所以我们提涨的时间比较早,今年3月初已经第一波起涨,但是市场接受程度比较差,真正成涨在3月底,宁夏地区区位优势不明显所以对市场紧密对不是特别紧,尤其是在涨价方面,但是降价的话就特别快。环保监测因为这个情况,100万吨的焦化厂需要资金投入是1-1.5亿,环保需要拿出4000万加一个环保设备的话,通常焦化厂不愿意做,只能限产、减产来达到环保要求的排放量。蒙、宁一带焦化厂都是为了配合煤矿的运营才建设的焦化厂,相当于焦化厂本来就不是主产业,一般老板必须投入3分之一左右的资金量在焦化方面,因此他们意愿不足,采煤可以销售到中国各地,煤的利润可以弥补焦炭利润的缺失,所以可以通过多开采煤,销售煤增加利润,没必要加大焦炭的产量。

山西和宁夏区域等焦化厂其实在投建上基本都能达到环保标准,但是焦化厂在生产过程中有一个特殊因素的存在,焦炉风机跳闸和停电的过程中会冒黄烟,冒黄烟在环保监测过程中视为排放,虽然是正常突发事件导致的,但是环保监测称为环保问题。

去年最困难的时候,15%的是闷炉零产量,25%焦炉是限产到一半左右,还有30%左右是产量70%,剩余20%是满产,没降过产。

焦化企业考虑乌海焦煤吗?蒙煤一般没有强粘结,胶质层也不高,很容易造成焦炭热强度不稳定,所以尽管有少量蒙古煤能替代主焦,但是大量数据测试显示,蒙古煤根本不能替代主焦煤。蒙煤配煤占比在5%,焦炭质量还能维持稳定,一旦达到5-10%,基本焦炭质量就会发生变化。蒙煤使用率的上限在宁夏是10%,不过山西不一样,山西有强粘结煤,可以用蒙煤来配,山西可以使用到25%左右。

(责任编辑:郭彪 UN832)

2016-09-28 13:51:38

澎湃新闻