China took five years to build a completely replace the imported | ballpoint pen ballpoint pen head head | | imports _ China News

For a long time, one thing has been pressure on the head of manufacturing in China:

> Reports about not ballpoint pen made in China

If it's not Prime Minister Li keqiang said, it is estimated that many people do not know. More than more than 3,000 enterprises, more than 200,000 working population, annual pens pens more than 40 billion ... ... China has become worthy of the country, but a series of numbers to be proud of, it is core technology and materials is highly dependent on imports, poor-quality counterfeit products flooding the embarrassing situation, a large number of ballpoint pen "ball" still needs to import.

China as a world manufacturing power, why should it be unable to achieve a completely independent research and development and production of small parts? "Ballpoint pens ask", but also "asked manufacturing in China"!

In November 2015, CCTV broadcast the dialogue program, beifa Group Chairman said the dilemma remains.

>

November 2015 CCTV broadcast the dialog programBut now things are changing! First look photos:

> Ballpoint pen production line

>

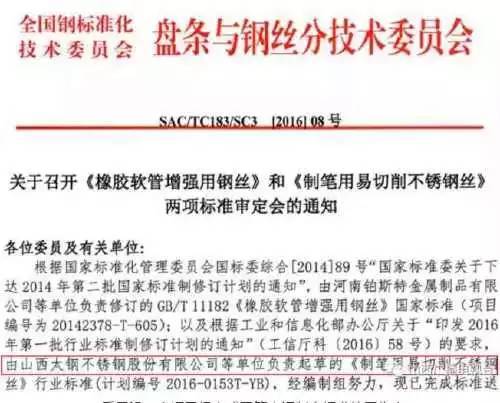

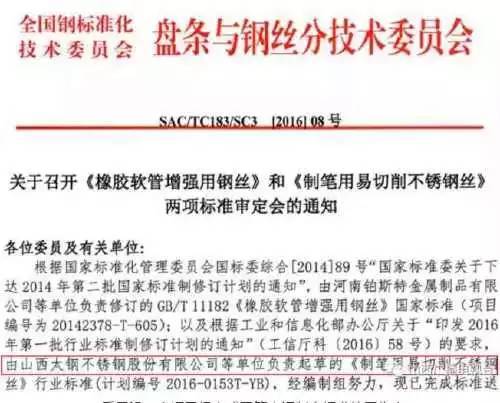

TISCO finished tip steel standard-setting workThis document shows that TISCO finished tip steel standard-setting work! "Wen Xin, Wen Xin, taking the new winning." Little "tip" torture, made in China offers great inspiration. A common Chinese Pen, write out Chinese power is driven by innovation.

Embarrassment: the core material is highly dependent on imports

Ningbo beifa pen line in each of the 3 billion ballpoint line, the digital zoom is 38 billion to China. As the world's largest producer of ball-point pen, behind glamorous figures, but is the embarrassment of core material is highly dependent on imports.

Ningbo beifa group quality manager Xu Jundao said: "the nib is written part of the steel we usually say. Since I entered the pen, pen stainless steel materials are from Japan, not only domestic, foreign pens the materials stainless steel is Japan. ”

Written into the ball and the ball on the tip. At present, the 0.5-1.0 mm diameter tungsten carbide ball can not only meet the needs of domestic production, China also exported. But only 2.3 mm diameter ball seat, whether it is the production of equipment or raw materials, long locked up in Switzerland, and Japan and other countries. Production of 38 billion a year, China needs a ton more than 120,000 prices to import more than 1000 tons of steel production tip, pay the 15 million US dollars.

This is a term from Switzerland written integrated production facilities of the company, and produce a small ballpoint pen head requires more than more than 20 operations. Written with different height and five guided the steps of ink in a trench, machining precision of up to 1 per thousand millimeters by orders of magnitude.

"The written key parts, such as explained, its dimensional accuracy are two Micron, its surface roughness required to 0.4 microns, such a technical requirement. "Ningbo beifa group quality manager Xu Jundao said.

In writing the top place, thickness 0.3-0.4 mm. High accuracy, very high performance demands on the stainless steel raw materials, not only easy cutting, processing does not crack, a little "tip" test in China.

Breakthrough for tens of billions of ballpoint pen put China "written"

In order to install tens of billions of ballpoint "Chinese writing", national open as early as 2011, a focus for research projects.

Taigang Group Technical Center senior engineer Wang Mian think steel to manufacture pen, trace element must use a lot of special, adjusted to the best performance of steel, small changes in trace element ratios will affect the quality of the steel, this ratio could not be found, Chinese pen will always need to import tip steel.

In order to focus the message, taigang Group Technical Center senior engineer Wang Mian said, because the development of this product there is no useful information, it is starting from a ratio of components from dozens of kilograms of refined, appointed to the various components of the times can't count.

Writing the production process is the core of enterprises abroad secret, Wang Mian and they have developed an unprecedented set of steel-making process. No references, only continue to accumulate data, parameters, methods of design and technology.

Breakthrough inspired by the homely "face", to live with moderate softness, will join the new "information", to take part in the corresponding steel industry "additives". Common additives are massive, if block to become thinner and thinner, fusion of molten steel and additives will more evenly, so that you can enhance machinability.

After five years of countless failed under the electron microscope, taigang group finally saw the "additive" uniform nib steel, test success in September 2016. After the massive steel-making more than 10 times, the first cutting of steel and finally came out. This batch of 2.3 mm diameter stainless steel wire, can write proudly "made in China" labels.

Beifa pen testing labs, steel raw materials produced by the pens are limit-testing, in the same perspective, continued writing every refill 800 meters there is no break, this is the sixth round of testing of this product.

Now, some written enterprises have begun to use over the next two years is expected to completely replace the imported.

> Editor: Zhang di

Article keywords:Ball-point pen imports

I want feedback

Save a Web page

Observer network

中国耗时五年造出圆珠笔头 完全替代进口|圆珠笔头|中国|进口_新闻资讯

很久以来,有个事儿一直压在中国制造业的头上:

>关于中国造不出圆珠笔头的报道

如果不是李克强总理说出来,估计好多人都不知道。3000多家制笔企业、20余万从业人口、年产圆珠笔400多亿支……中国已经成为当之无愧的制笔大国,但一连串值得骄傲的数字背后,却是核心技术和材料高度依赖进口、劣质假冒产品泛滥的尴尬局面,大量的圆珠笔笔头的“球珠”还需要进口。

中国作为世界制造业大国,为何却无法实现一个小小零件的完全自主研发和生产?“圆珠笔之问”,更是“中国制造业之问”!

在2015年11月央视播出的《对话》节目里,贝发集团董事长表示,困境依旧。

>

2015年11月央视播出的《对话》节目 但是,现在事情有了新变化!先看一组图:

>圆珠笔的生产线

>

太钢完成笔尖钢制定标准的工作 这份文件显示,太钢完成了笔尖钢制定标准的工作!“闻新则喜、闻新则动、以新制胜”。小小“笔尖”拷问,给中国制造带来巨大启示。一支司空见惯的中国笔,书写出的是创新驱动的中国力量。

尴尬:核心材料高度依赖进口

在宁波贝发笔业生产线上,每年有30亿支圆珠笔下线,这个数字放大到中国是380亿支。作为世界上最大的圆珠笔生产国,光鲜数字的背后,却是核心材料高度依赖进口的尴尬局面。

宁波贝发集团品质部经理徐君道说:“笔尖钢我们一般说的就是笔头部分。我进入制笔行业以来,笔头不锈钢材料都是从日本进来的,不仅是国内,国外的制笔材料不锈钢材料也是日本的。”

笔头分为笔尖上的球珠和球座体。目前,直径0.5-1.0毫米的碳化钨球珠中国不仅可以满足国内生产需要,还大量出口。但直径仅有2.3毫米的球座体,无论是生产设备还是原材料,长期以来都掌握在瑞士、日本等国家手中。中国每年要生产380亿支笔需要用一吨12万的价格进口1000多吨生产笔尖的钢材,付出外汇1500万美元。

这是一种来自瑞士公司的笔头一体化生产设备,生产一个小小的圆珠笔头需要二十多道工序。笔头里面有不同高度的台阶和五条引导墨水的沟槽,加工精度都要达到千分之一毫米的数量级。

“笔头的关键部位,比如碗口,它的尺寸精度都是在两个微米,它的表面粗糙度要求在0.4微米,这样一个技术要求。”宁波贝发集团品质部经理徐君道说。

在笔头最顶端的地方,厚度仅有0.3-0.4毫米。极高的加工精度,对不锈钢原材料提出了极高的性能要求,既要容易切削,加工时还不能开裂,小小“笔尖”考验着中国制造。

突破:给数百亿圆珠笔安上“中国笔头”

为了给数百亿支圆珠笔安上“中国笔头”,国家早在2011年就开启了这一重点项目的攻关。

太钢集团技术中心高级工程师王辉绵认为,钢材要制造笔头,必须用很多特殊的微量元素,把钢材调整到最佳性能,微量元素配比的细微变化都会影响着钢材质量,这个配比找不到,中国的制笔行业永远都需要进口笔尖钢。

为了提炼材料,太钢集团技术中心高级工程师王辉绵说,因为开发这个产品没有可借鉴的资料,都是从一个成分的配比从几十公斤的开始炼,各种成分加入多少这个次数没法统计了。

笔头产品的生产工艺是国外企业的核心机密,王辉绵他们必须自主开发一套前所未有的炼钢工艺。没有任何参考,只能不断地积累数据、调整参数、设计工艺方法。

突破的灵感来自家常的“和面”,面要想活得软硬适中,就要加入新“料”,相对应的钢水里就要加入工业“添加剂”。普通的添加剂都是块状,如果能把块状儿变细变薄,钢水和添加剂就会融合的更加均匀,这样就可以增强切削性。

经过五年数不清的失败,在电子显微镜下,太钢集团终于看到了“添加剂”分布均匀的笔尖钢,试验在2016年9月取得成功。大规模炼钢十多次后,第一批切削性好的钢材终于出炉了。这批直径2.3毫米的不锈钢钢丝,可以骄傲的写上了“中国制造”的标志。

在贝发笔业的测试实验室,用太钢原料生产出来的笔芯正在进行极限测试,在同一个角度下,每支笔芯都要连续不断地书写800米不出现断线情况,这已经是对这一产品的第六轮测试。

现在,一些笔头企业已经开始使用,在未来两年有望完全替代进口。

>责任编辑:张迪

文章关键词: 圆珠笔头 中国 进口

我要反馈

保存网页

观察者网