The reality: each 25 kg worth 3 million Chinese Treasury what kind | | Treasury gold bullion bullion _ news

Every year during the Spring Festival, gold jewelry is usher in the peak season for consumption in one year. According to the latest statistics of the China Gold Association show that in 2016, China's gold consumption was 975.38 tons, for four consecutive years as the world's largest gold consumer.

So, you know that our national reserve – Treasury gold standard gold ingots of gold look like? Do you know how it is produced? Recently, the CCTV reporters into the gold standard bullion production enterprises in China for the first time, exclusive secrets of the whole production process.

How Treasury standard bullion is tempered?

>

China banknote printing and minting Corporation subsidiary of Chengdu banknote printing company is the only manufacturer in China National gold standard bullion business, has a history of more than 50 years.

>

As precious metals production enterprises, management of product safety is key, in key positions 24 hours monitoring, handling, transfer will clear management system, all necessary means for ensuring the safety of products.

Bullion production of the first process is purified is substandard quality rough material in specific processes to remove impurities, meet the required standards.

At present, the enterprise is used in extraction and purification, this is a common international gold purification method. Rough in the dissolving tank, by extracting the restore into powder.

>

After washing and drying of powder, you will move on to the next casting process, so after extracting powder fineness, directly affects the bullion reserves the final color.

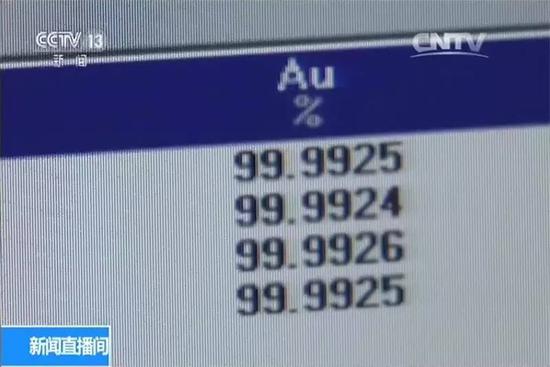

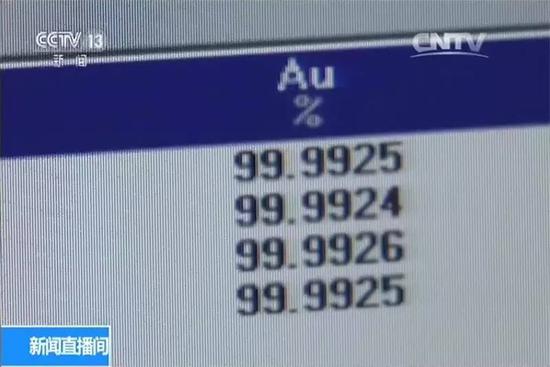

Senior technician Zeng Heyin said: "international standard gold ingots require a 4-9, but this is 4 out of 92 (99.992%), even higher than the international standard, so our international standard gold ingots, are exempt in the international market. ”

He Lian 9999 pure gold?

Powdered into gold bullion? In a casting workshop in bullion production, don't see the modern assembly line, workers here are mostly used in production in a very traditional way. According to reports, China's reserves of gold in this traditional craft has a history of more than half a century.

>

Purified gold first after 1300 degree high temperature melts into liquid gold. Gold ingot casting of key positions must be operated by experienced master craftsman, the furnace melts good Goldwater about 70 kg, in interaction with the four workers, casting solidification in the mold of custom, each gold ingot weight 12.5 kg must be strictly controlled, in line with the international standard gold bullion standard.

>

Solidification of ingots through pickling removes oxides, cools the surface, then after water immersion, a standard gold ingot shape.

>

All furnace, metal casting is complete, melting pot the remaining tailings to digital management in strict accordance with the provisions for recycling.

Casting Ma Guangju senior technicians told reporters that the tailings to be weighed to verify weight and qualified products are delivered to the Treasury, weighed in and picking the numbers entirely.

"Fire assay": "fire"

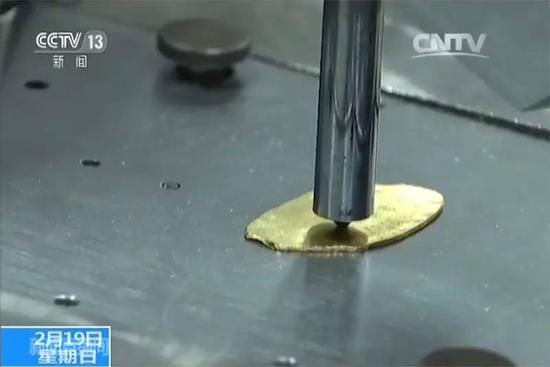

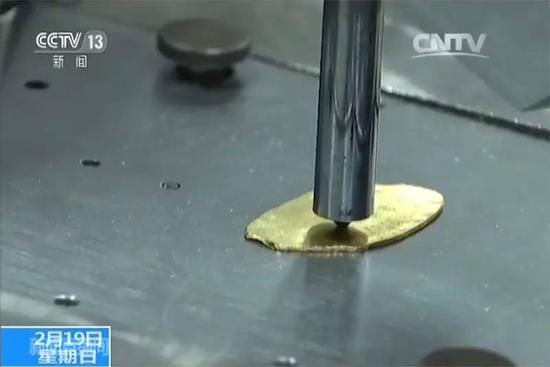

After gold ingots cast, how do you know whether this batch of bullion quality standards? This requires color detection. Gold ingot casting process, every stove must be sampled to gold composition of the sample.

Fineness and weight is most precious metals production, two of the most important indicators, color accuracy, relies on the advanced and reliable analysis and detection technology and rigorous analysis process.

>

>

Color is above 99.95 gold, usually using spectrum analysis method, this approach can be obtained quickly within 30 seconds of the Gold master composition and impurity content, color, under 99.95 gold often used "fire assay".

>

Analysis engineer Zhang, the "fire assay" is a very old method, has a long history of recognition at the international level is high, is an international classic methods.

Specifically, is lead into a spherical sample packages in nearly 1000 degree high temperature furnace, volatile impurities in the oxidation of the sample, by calculating the proportion of remaining gold, the fineness of the sample is obtained.

Standard gold ingots 12.5 kg to move is not easy

Bullion produced, after intensity classification also uses the balance weighing and metering. Is a mechanical balance weighing scale, the scale is more stable, accurate to 0.01 grams.

After weighing bullion, have to play, color, date of manufacture, serial number on hand may play in every piece of gold bullion, bullion identity that each block.

>

Why use the manual method? Ma Guangju explained, because gold ingots surface curve is not exactly the same, if the machine number, the local depth of play is not clear.

>

After purification, casting, inspection, weighing, marking these five procedures, standard gold bullion finish all production processes.

>

CCTV reporters: now my eyes shine, which is produced by the international inspection standards of gold bullion, which weighs 12.5 kg of gold bullion, I an not entirely his hand up. This piece of gold bullion worth an estimated 3 million Yuan, China was the gold in vault storage.

>: Tang Wu Yan

Article keywords:The Treasury gold bullion

I want feedback

Save a Web page

CCTV

揭秘:每块25斤价值300万的中国国库金锭什么样|国库|金锭_新闻资讯

每年的春节期间,黄金类饰品都迎来一年中消费的旺季。据中国黄金协会最新的统计数据显示,2016年,中国黄金消费量975.38吨,连续四年成为世界第一黄金消费国。

那么,你知道我们国家的储备黄金——国库金标准金锭长什么样吗?你知道它是怎么生产出来的吗?近日,央视记者首次进入中国储备黄金标准金锭生产企业,独家揭秘生产全过程。

国库标准金锭是如何炼成的?

>

中国印钞造币总公司旗下的成都印钞有限公司是中国唯一一家生产国家储备黄金标准金锭的企业,已经有50多年的历史了。

>

作为贵金属生产企业,产品安全是管理的重点,在重点岗位24小时监控、经手必数、交接必清等管理制度,都是确保产品安全的必要手段。

金锭生产的第一道工序是提纯,就是把成色不达标的粗金原料经过特定工艺去除杂质,达到规定标准。

目前,企业采用的是萃取提纯,这是一种国际上通用的黄金提纯方法。粗金放进溶解罐,通过萃取还原,变成金粉。

>

金粉经过清洗、烘干后,就将进入下一道熔铸工序,所以萃取后金粉的成色,直接影响了储备金锭最终成色。

高级技师曾和银说:“国际标准金锭都要求达到4个9,但是我们这个都是在4个92(99.992%)以上的,比国际标准还要高,所以我们的国际标准金锭,在国际市场上都是免检的。”

如何炼就9999纯金?

金粉如何变成金光闪闪的金锭呢?在金锭生产的一个熔铸车间里,看不到现代化的流水线,这里的工人大多是采用一种很传统的方式在生产。据介绍,中国的储备黄金用这种传统的工艺已有半个多世纪的历史。

>

提纯后的金粉首先要经过1300度高温融化成金水。金锭熔铸的关键岗位都必须由经验丰富的老师傅进行操作,这一炉融化好的金水大约有70公斤,在四个工人的相互配合下,浇铸进定制的模具里凝固,每一块金锭的重量必须严格控制在12.5公斤,符合国际标准金锭的公差标准。

>

凝固后的金锭要经过酸洗去除表面氧化物、冷却,再经过清水的浸泡,一块标准金锭就基本成型了。

>

一炉金水在全部浇铸完成后,熔炉里剩余的尾料要严格按照数字管理规定,进行回收处理。

熔铸高级技师马光举告诉记者,尾料也要过秤核实重量,和合格产品一起交付库房,称重的数字要和领料的数字完全对得起来。

“火试金”:“真金不怕火炼”

金锭浇铸成型后,怎么知道这一批次的金锭成色是否达标?这就需要成色检测。在金锭浇铸过程中,每一炉都要取样,对样品进行黄金成分的检测。

成色和重量是贵金属生产最基本、最重要的两个指标,成色的准确,依靠的是先进可靠的分析检测技术和严格的分析检测流程。

>

>

成色在99.95以上的黄金,通常采用光谱分析检测法,这种方法可以在30秒内快速得出黄金的主成分和杂质含量,成色在99.95以下的黄金通常采用“火试金”法。

>

分析检测师张波介绍,“火试金”是很古老的方法,有着悠久的历史,在国际上的认可度比较高,是国际经典的判定方法。

具体来说,就是用铅把试样包裹成球形放进接近1000度高温的熔炉,试样中的杂质会氧化挥发,再通过计算剩余黄金比重,得出试样的成色。

标准金锭12.5公斤 想要搬动不容易

生产出来的金锭,在经过成色检测之后还要使用天平称重计量。称重的秤是一个机械天平,这种秤比较稳定,可以精确到0.01克。

称重后的金锭,还要进行打号,把成色、生产日期、序列号用纯手工的方法打在每一块金锭上,也就是给每块金锭一个身份认证。

>

为什么要采用手工的方法打号?马光举解释,因为金锭表面的曲线不是完全一致的,如果采用机器打号,会存在局部深度不够而打不清的情况。

>

经过提纯、熔铸、检测、称重、打号这五道工序,标准金锭就完成了全部的生产过程。

>

央视记者:现在我的眼前金光闪闪,这就是刚刚生产出来的国际免检标准的金锭,这一块金锭的重量是12.5公斤,我一只手完全拿不起来。这一块金锭大约价值300万人民币,中国金库里存放的就是这种储备黄金。

>责任编辑:吴颜

文章关键词: 国库 金锭

我要反馈

保存网页

央视